Comprehensive Protocol for Nitrocellulose Isolation: A Forensic Chemistry Milestone

Introduction Nitrocellulose, discovered in 1846 by Christian Friedrich Schönbein, has proven to be one of the most significant materials in the production of smokeless gunpowders. As a nitrated cellulose ester polymer, nitrocellulose’s applications range from varnishes and films to explosives and propellants. Despite its widespread use, the isolation and characterization of nitrocellulose have been a persistent challenge for researchers due to its chemical complexity and structural variability. This blog explores a groundbreaking protocol for isolating nitrocellulose from single-, double-, and triple-base gunpowders, shedding light on its implications for forensic investigations and industrial applications.

Understanding Nitrocellulose Nitrocellulose is composed of monomer units joined by β-1,4 bonds, with varying degrees of nitration that influence its nitrogen content. The degree of substitution (D.S.) determines the percentage of hydroxyl groups replaced by nitrate groups. For instance:

- D.S. of 1 corresponds to 6.76% nitrogen.

- D.S. of 2 reaches 11.11% nitrogen.

- D.S. of 3 achieves 14.15% nitrogen.

This variability dictates its use. Nitrocellulose with lower nitrogen content (<12%) is utilized in non-explosive applications like films and coatings, while higher nitrogen content (>12%) makes it ideal for explosive materials. Gunpowders are classified into three categories based on their composition:

- Single-base gunpowders: Primarily nitrocellulose.

- Double-base gunpowders: Contain nitrocellulose and nitroglycerin or dinitrotoluene.

- Triple-base gunpowders: Include nitrocellulose, nitroglycerin, and nitroguanidine.

Challenges in Isolation and Analysis Despite its importance, nitrocellulose isolation presents several challenges:

- Complex Chemical Structure: Its high molar mass and intricate polymeric structure complicate analysis.

- Lack of Reference Materials: Most commercially available standards lack sufficient nitrogen content, making them unsuitable for explosives analysis.

- Incomplete Isolation: Traditional methods often result in colloidal precipitates or co-precipitates, impeding accurate characterization.

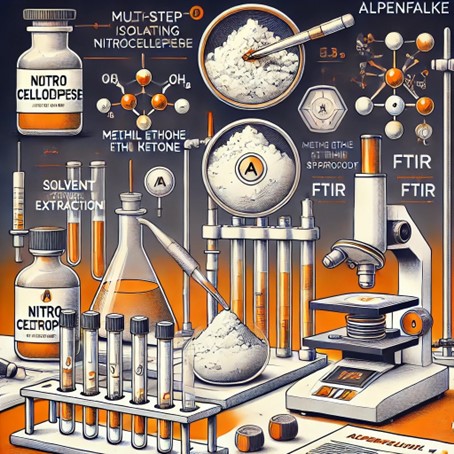

The New Isolation Protocol A revolutionary multistep solvent extraction protocol has been developed to address these challenges. This method ensures efficient separation of nitrocellulose from other gunpowder components and provides a reliable foundation for forensic and industrial analysis.

Key Steps in the Protocol

- Methanol Extractions:

- Three successive extractions remove nitroglycerin, stabilizers (e.g., diphenylamine, ethyl-centralite), and other organic additives.

- Operates at 35°C to prevent degradation of nitrocellulose.

- Dichloromethane Extraction:

- Targets and removes colorants and organic plasticizers.

- Final Methanol Extraction:

- Facilitates polar extraction and prepares the sample for subsequent steps.

- Water Extractions:

- Conducted at 35°C for single- and double-base gunpowders.

- Triple-base gunpowders require additional water extractions at 75°C due to higher nitroguanidine content.

- Methyl Ethyl Ketone Solubilization:

- Nitrocellulose is dissolved, separating inert components like graphite.

This systematic approach yields high-purity nitrocellulose suitable for further analysis.

Characterization Using FTIR Spectroscopy Fourier-Transform Infrared Spectroscopy (FTIR) plays a crucial role in characterizing the isolated nitrocellulose. Key observations include:

- Hydroxyl Group Vibrations (3600–3400 cm⁻¹):

- Bands in this region indicate residual hydroxyl groups.

- More pronounced in low-nitration samples.

- C=O Vibrations (1200–1000 cm⁻¹):

- Attributed to glucopyranose cycles in the polymer backbone.

- Nitrate Group Vibrations (750–690 cm⁻¹):

- Stronger in low-nitration samples.

These spectral features provide a fingerprint for identifying nitrocellulose and its nitration degree.

Applications and Implications The new protocol for nitrocellulose isolation has broad implications for multiple fields:

Forensic Investigations

- Trace Analysis: The method enables precise identification of gunpowder residues in crime scenes.

- Explosive Identification: Isolated nitrocellulose can be compared to known samples to determine the origin of explosives.

Industrial Quality Control

- Manufacturing Consistency: Ensures the production of high-quality nitrocellulose for propellants and explosives.

- Regulatory Compliance: Provides reliable data for adhering to safety and environmental standards.

Scientific Research

- Material Development: Supports the creation of advanced nitrocellulose-based materials.

- Environmental Studies: Assists in analyzing nitrocellulose degradation in soil and water.

Advantages of the Protocol

- High Purity: Achieves effective separation of nitrocellulose from other components.

- Reproducibility: Suitable for routine use in forensic and industrial laboratories.

- Comprehensive Analysis: Enables detailed characterization using advanced spectroscopic techniques.

Conclusion The development of a robust protocol for nitrocellulose isolation marks a significant milestone in forensic and analytical chemistry. By addressing long-standing challenges, this methodology enhances our ability to analyze and understand nitrocellulose-based gunpowders. As forensic investigations and industrial applications grow increasingly complex, such innovations will continue to play a vital role in advancing safety, security, and scientific discovery.

Stay tuned with Alpenfalke for the latest developments in chemical analysis and forensic technologies.